- Home

- Hochschule

-

Studium

- Studienangebote

-

Beratung

- Studienorientierung

- Zentrale Studienberatung

- Studienfachberatung

- Psychosoziale Beratung

- Studienfinanzierungsberatung und Stipendien

- Schreibberatung

- Studieren mit beruflicher Qualifikation

- Studieren mit ausländischen Zeugnissen

- Studieren mit Handicap

- Studieren mit Familie

- Informationen für Schulen

- Auslandsaufenthalt

-

Bewerbung

- Auswahlgrenzen und Vergabeverfahren (NC)

- Bewerbungsportal

- Bewerbung Schritt für Schritt: Von der Bewerbung bis zur Einschreibung

- Bewerbung für ein höheres Fachsemester

- Bewerbung mit beruflicher Qualifikation

- Gasthörerschaft und Zweithörerschaft

- Kontakt Studierendenservice

- Losverfahren

- Promotion

- Sonderanträge

- Studiengang wählen

- Wer kann an der HSBI studieren?

- Studienstart

-

Studium organisieren

- Studierendenservice

- Abschlussunterlagen

- Anerkennung von Leistungen

- Anträge einreichen

- Beurlaubung

- CampusCard

- Einreichung schriftliche Arbeiten

- Erstattung

- Exmatrikulation

- IT-Services

- Online-Serviceportale (LSF/CAT)

- Prüfungsangelegenheiten: Ordnungen, Modulhandbücher

- Rücktritt von einer Modulprüfung

- Rückmeldung

- Semesterbeitrag

- Semesterticket (Studi-Deutschlandticket)

- Semester- und Vorlesungszeiten

- Studienbezogene Auslandserfahrung

- Studiengebühren

- Vorlesungsverzeichnis

- Rund ums Studium

- Fachbereiche

- Forschung

- Transfer

- Weiterbildung

- Internationales

- Karriere an der HSBI

Adaptive Sensoraktivierung mit aktivem/maschinellem Lernen für IoT-gestützte Qualitätssicherung

Projektübersicht

| Anzahl Studierende | 1-2 |

| Art | Studienprojekt |

| Projektverantwortung | Dr. Alaa Othman Prof. Dr.-Ing. Wolfram Schenck |

| Projektkontext |

Projekt innerhalb des Center for Applied Data Science Gütersloh (CfADS) mit hochschulinternen Partnern. |

In the rapidly evolving landscape of industrial environments, the proliferation of IoT sensors has led to an unprecedented generation of data. However, this surge in data comes with a significant challenge - efficient management and utilization. The extensive use of sensors to monitor various parameters, processes, and conditions in factory environments results in a tremendous volume of data streams. This presents challenges in terms of data transmission, network bandwidth utilization and, most importantly, the power consumption of battery-powered IoT devices.

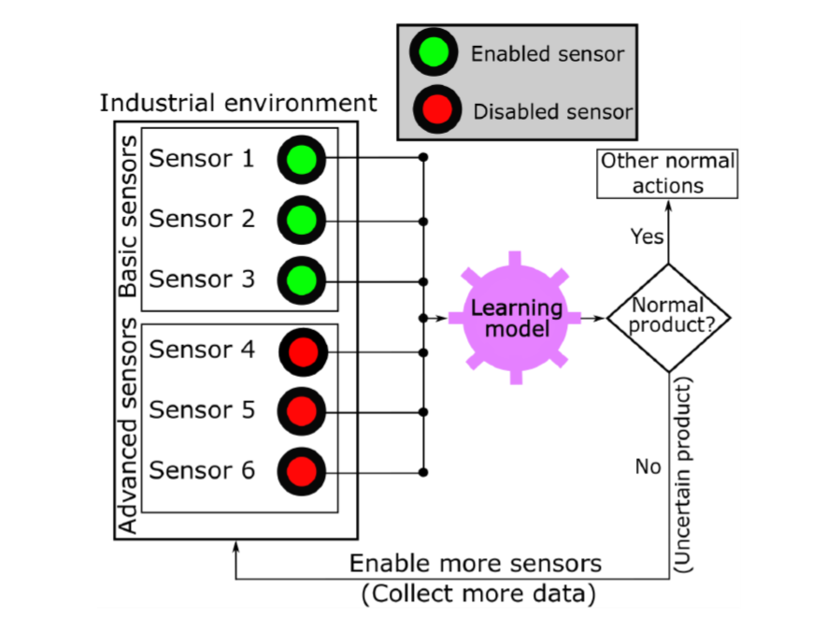

To address these challenges, we present an adaptive sensor activation system infused with active learning algorithms. The core motivation is to harness the power of data-driven decision making to optimize sensor utilization. Rather than indiscriminately activating all sensors in real time, our system intelligently identifies patterns in product data that indicate uncertainties or potential errors. By selectively activating additional sensors based on these predictions, we achieve the dual goal of ensuring a comprehensive inspection of products and reducing the strain on network resources. This not only allows for more in-depth analysis when needed, but also conserves energy-a critical consideration in IoT environments with battery-powered devices.

In practice, our adaptive sensor activation system finds its ideal application in environments where IoT sensors and wearables play a central role, such as modern factories. In our IoT factory in Gütersloh, consider a scenario where Robotinos and other IoT devices monitor and track various processes. Through active learning, the system can identify anomalies or uncertainties in the monitored data streams. In response, it strategically activates additional sensors for closer inspection, ensuring that network congestion is minimized, energy is conserved, and product quality is rigorously maintained. This paradigm shift in sensor network management holds great promise for improving the efficiency, sustainability, and overall performance of industrial IoT environments.

The student(s) will develop and implement an adaptive sensor activation system for industrial IoT environments. This system will integrate active learning algorithms to intelligently activate sensors based on patterns identified in product data, specifically targeting uncertainties and potential errors. The goal is to optimize sensor usage and address the challenges posed by large data streams in large-scale industrial environments. Students will work on refining and implementing the algorithm, ensuring that additional sensors are selectively activated, minimizing network congestion, and conserving energy

in environments with battery-powered devices. The practical application of this system will be demonstrated in our IoT factory, improving both data efficiency and product quality through intelligent sensor activation.

Bezug zum Thema Data Science

The proposed research aligns seamlessly with core data science principles, integrating active learning algorithms into industrial IoT environments. This aligns with the research master's curriculum, which emphasizes advanced techniques for pattern recognition, predictive analytics, and data-driven decision making. The project provides an opportunity for students to explore and apply cutting-edge data science methods in a real-world context, fostering a deep understanding of how these techniques contribute to the optimization of sensor networks and resource utilization in industrial environments.

Verfügbare Ressourcen

- Access to a fully-equipped IoT factory: The project benefits from the availability of a comprehensive IoT factory that facilitates the creation of simulations, data collection, and real-world testing. This resource allows students to work in an authentic industrial environment, enhancing the practical applicability of their research.

- Expert Oversight: The project is supported by knowledgeable and experienced supervisors who are well-versed in data science techniques, including active learning, as well as IoT and industrial applications. Students can tap into this expertise for guidance, feedback, and mentorship throughout the research process, ensuring the quality and relevance of their work.

- Collaborative spaces: The CfADS group at FHBielefeld provides collaborative spaces where students can engage with peers, share insights, and leverage additional resources. These hubs foster an environment that encourages interdisciplinary collaboration and promotes a holistic approach to problem solving.

- No additional hardware required: The project leverages existing hardware resources within the IoT factory, eliminating the need for additional investment. Students can seamlessly integrate their research into the existing infrastructure, streamlining the implementation of adaptive sensor activation using active learning algorithms.

Projektplan

First Semester: Project Setup and Exploration

Become familiar with the IoT factory infrastructure and data collection processes. Develop a clear understanding of industrial processes and sensor networks. Begin a literature review on active learning in IoT environments. Define initial requirements for the adaptive sensor activation system. Create a Research Exposée.

Second Semester: Initial Development and Prototyping

Develop a prototype of active learning algorithms in a simulated environment. Implement basic sensor activation mechanisms based on active learning. Start integrating the prototype with the IoT factory for initial testing. Investigate potential challenges and refine the system design. Publish a Technical Report about the research area.

Third Semester: System Refinement and Integration

Enhance the active learning algorithms for more sophisticated sensor activation. Integrate the system with real-time data from the IoT factory. Evaluate the performance of adaptive sensor activation in a controlled environment. Begin to explore energy saving aspects for battery powered devices. Publish a Paper about the results on a conference.

Fourth Semester: Optimization and Final Evaluation

Optimize the system for efficiency, minimizing unnecessary sensor activations. Fine-tune active learning algorithms based on feedback and performance metrics. Conduct extensive testing in various scenarios within the IoT factory. Summarize results, compare with existing methods, and provide recommendations for further improvements. Master's thesis and colloquium

Eignungskriterien

Mandatory: Strong programming skills, particularly in languages suitable for IoT applications (e.g., Python).

Optional:

- Familiarity with machine learning concepts and algorithms.

- Understanding of IoT systems and sensor networks.

Erwerbbare Kompetenzen

- Proficiency in implementing and using active learning methods, especially in the context of adaptive sensor activation.

- Hands-on experience with IoT systems, including working with sensor data, communication protocols, and network optimization.

- Competence in developing and integrating machine learning algorithms within an IoT environment.

- Knowledge and practical skills in designing and executing experiments for testing and optimizing adaptive sensor activation strategies.